Tennsmith LM Series Shear

SKU: TLMSHEAR

Call for Status and Pricing

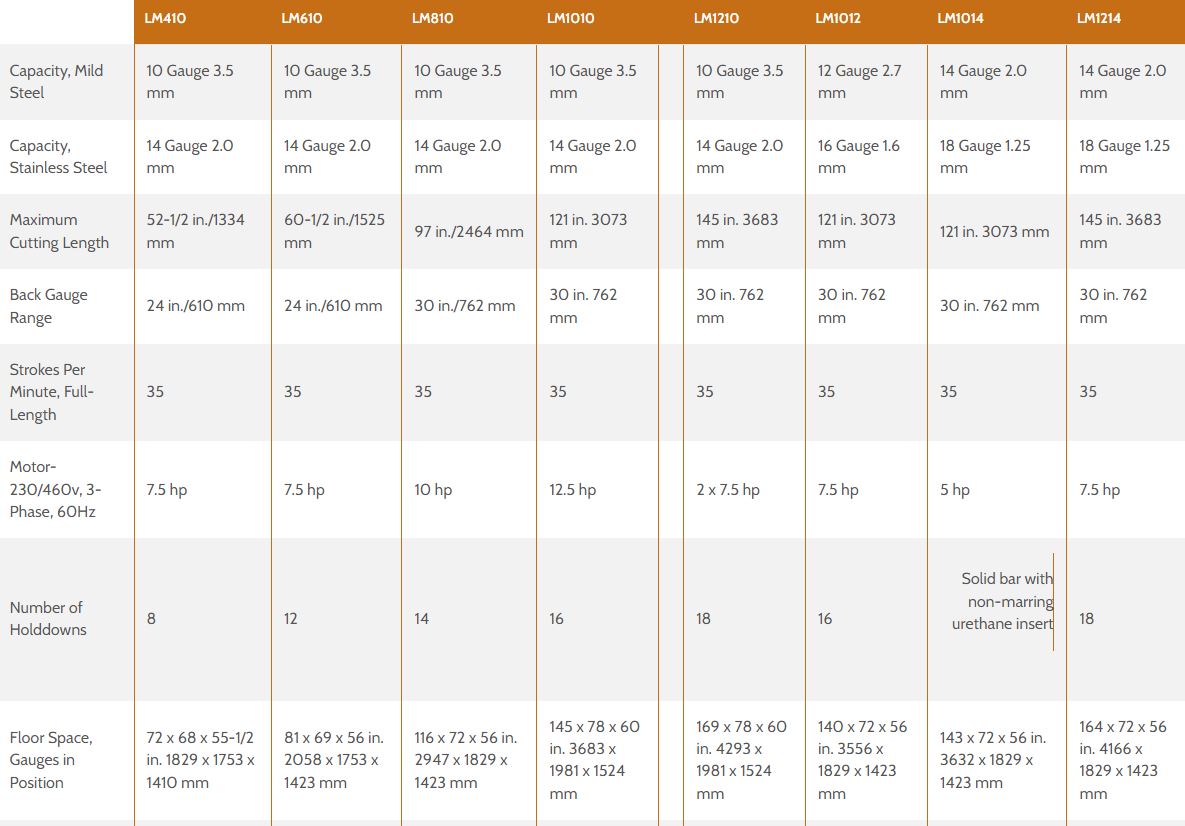

Models LM410, LM610, LM810, LM1010, LM1012, LM1014 and LM1214 incorporate the unique 2x back gauge system. This allows the operator to move the backstop from 0 up to 30 inches (0 to 24 inches for Model LM410) in approximately 2 seconds with only two rotations of the handle. An optional digital readout is available for this system. The LM Series shears are standard with four edge, high carbon/high chromium (HCHC) top and bottom blades, solid-bar hold-down with non-marring urethane insert, single, continuous and job stroke cycles, motor reverse switch, precision-machined table with hand well, dual inch/metric inlaid bed scales and non-metallic gibs. The LM410 model incorporates all of the popular LM series features into this 52-1/2″ cutting length, 10-gauge mild steel capacity shear. Model LM610 has a rated capacity of 10-gauge mild steel with a maximum cutting length of 60-1/2 inches. LM Series shears are now available in an optional “Performance Package” configuration which includes a 5′ squaring arm, a pair of front support arms, and an air-operated sheet support that is available in two styles:

- System R drops the supported material to the rear of the machine

- System F returns the supported material to the front of the machine via a front return chute/

- 2X backgauge with digital readout: measurs in 0.001″ increments

- 10′ and 12′ length squaring arms which can be mounted left or right and have inlaid inch/metric scaling and adjustable guide block.

- Powered “Go-To” backgauge system featuring a twin ball screw design with a 30″ travel.

- Material cart (for LM1014 model)

- stroke counter

- protractor for angled cuts

- High-speed motors for increased cutting cycles

- t-slotted table (supports arms with inlaid inch/metric scales)

Similar Products

Get a Quote

Purchase Inquiry

Get Pricing