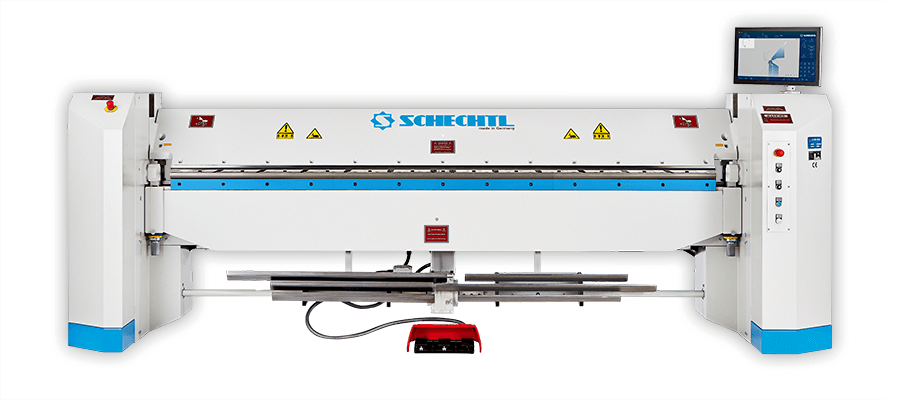

Schechtl MAX-F 10′ x 16ga CNC Folder

SKU: MAXF

In Stock • Ready To Ship

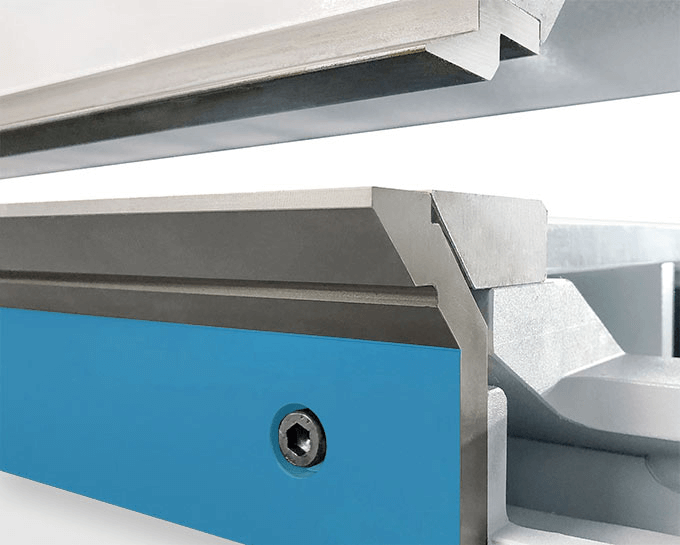

The Schechtl MAX is the single most popular selling folder in North America. But that was not good enough for the engineers at Schechtl. We are proud to introduce the MAX-F and MAX-I! Everything you have always loved about the MAX, reengineered to bend faster, hem better, and increase flexibility. The legendary strength of the MAX has been improved with redesigned clamping, bottom, and folding beams. The clamping and bottom beams are stiffer for superior hemming and more clearance between the gauge table and the clamping beam. The folding beam, driven by the new electric direct-drive system is more efficient, with faster bending speeds and better bending consistency. Couple this with the newly designed dual servo-drive gauge system for lightning-fast gauging, and you have a machine unrivaled by anything in the industry.

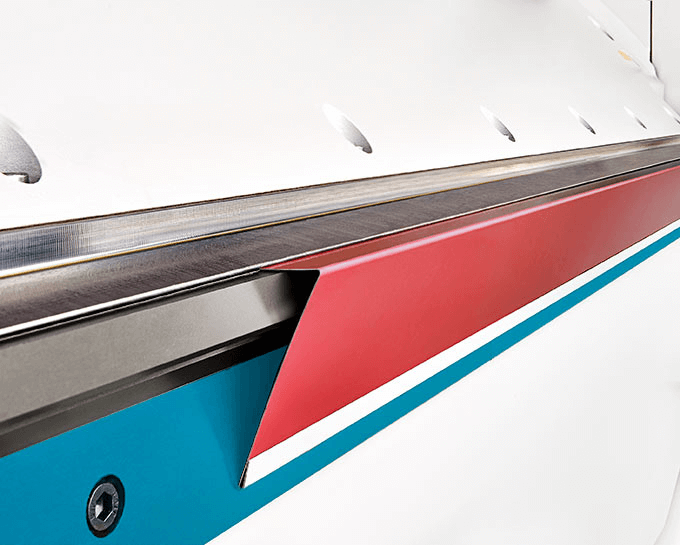

MAX-F

All the latest and greatest features of the MAX-I plus new F-Geometry – first of its kind in a short folding machine. At the front of the machine, an extra .55” of space behind pivot provides more folding flexibility and decreases the need to push against deeper profile geometries during folding. Bending hat channels, corrugations, vented ridges, pitch correct drip edges and bigger J’s was never easier. The F-Geometry creates more free space taking the already versatile MAX to a whole new level.

Benefits

-

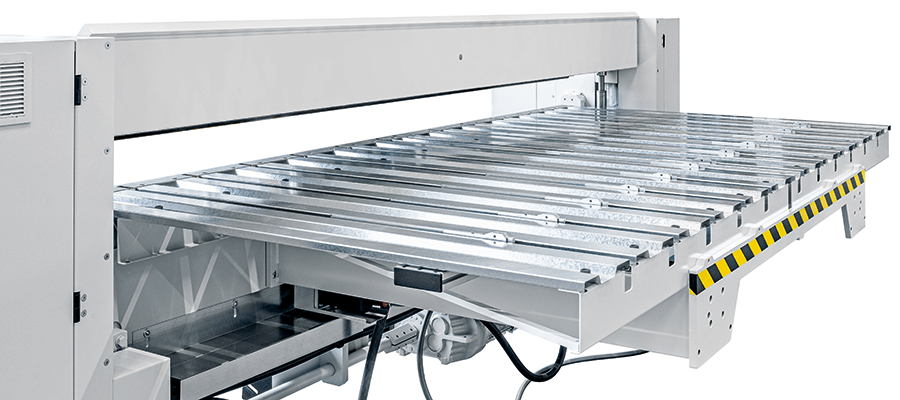

- Motor operated back gauge including 12 safety stop fingers

- Easy adjustment of bending beam and upper beam

- Bearings and guideways are maintenance free

- All NEW Servo Drive backgauge 53% faster — increase productivity

- Movable foot switch

- Eccentric drive upper beam

- Upper beam, lower beam and bending beam are welded steel design

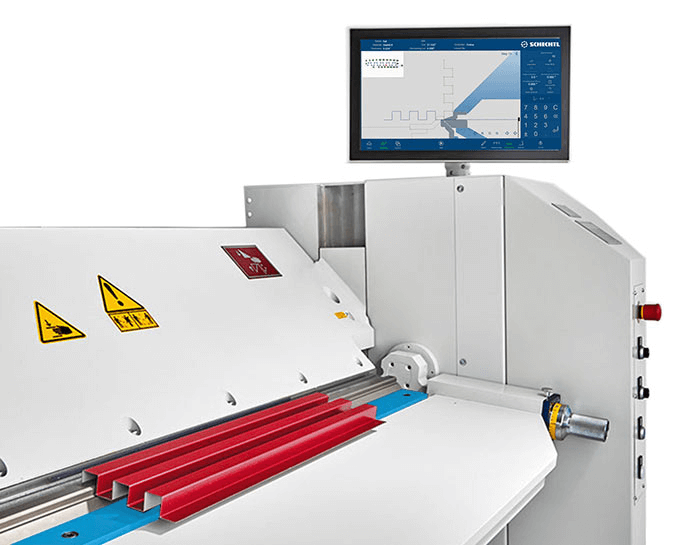

- CNC Touch Control with frequency inverter

Control

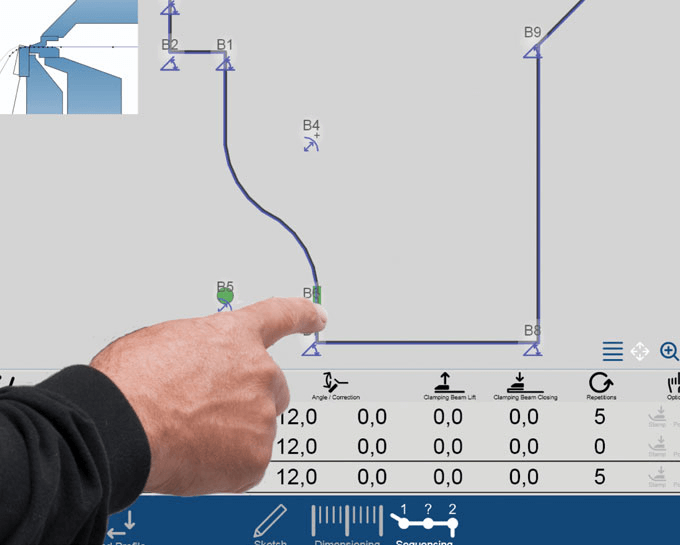

Both the MAX-I and MAX-F are equipped with iFold touch screen interface allowing you to literally drag and draw parts in real time, creating the actual dimensions as you go. It tells you when to flip, rotate and move the part to finish it. Decrease production prep time and folding errors with iFold technology. Also use the J-Bend app for mobile programming to save you time back at the shop. The iFold program Explorer function allows the operator to organize and store parts in an endless number of ways: part number, job name, project name or number, etc. Not to mention the massive core parts library filled with industry standard parts. Besides linking to the mobile app, the control can network to your office computers, multiple machines or with MetalForming, LLC. for remote support.Specifications

| Working Length | 122″ |

| Capacity | 16 ga CRS |

| Maximum Hemming Capacity | 24 ga CRS |

| Upper Beam Stroke | 5.51″ |

| Folding Beam Arc, with 20° | 0°-160° |

| Backgauge Depth | 39.5″ |

| Backgauge Accuracy | ±.004 |

| Electrics – 3 phase, 60 Hz @ 20 amps | 230V |

| Weight | 7,099 lbs. |

| Length | 165.62″ |

| Depth | 84.61″ |

| Height | 72.95″ |

Specifications

| Manufacturer | Metalforming |

|---|---|

| Inventory Type | New |

| Machine Type | CNC Folder |

| Applications | Roofing |

| Item Number | MAXF |